Drive Systems

AccuStaltic pumps are designed to be driven by several different types of motors. This allows a complete selection of industry standard electric motors and gearboxes and also hydraulic motors for mobile and other special situations. For electric applications, Ledebuhr Industries offers a choice of washdown and stainless steel AC electric motors coupled to clutches and washdown grade gear boxes in ratios to suit most application needs.

Fixed Speed Electric:

|

When simple discrete flow rates are required, a fixed speed motor attached to the appropriate gear box and tubing size can create the desired flow. Standard fixed speed motors running on 60 Hz power are available in 1725 and 3450 speeds. These can be coupled to one of several standard gearboxes with ratios from 5:1 to 50:1 generate the following pump speeds.

Gearbox Ratio |

Fixed Speed RPM (1725 RPM Motor) |

Fixed Speed RPM (3450 RPM Motor) |

50:1 |

34.5 |

69 |

20:1 |

86.25 |

172.5 |

10:1 |

172.5 |

345 |

7.5:1 |

230 |

460 |

5:1 |

345 |

NA |

|

Variable Speed Electric:

To control the exact flow rate AccuStaltic pumps are driven by a variable speed motor controlled by a Variable Frequency Drive (VFD). These motors coupled with our standard gear boxes create adjustable pumps speeds in the following ranges:

Gearbox Ratio |

Variable Speed Range RPM

(1725 RPM Base Speed Motor) |

50:1 |

5-50 |

20:1 |

25-125 |

10:1 |

50-250 |

7.5:1 |

65-350 |

5:1 |

100-450 |

|

|

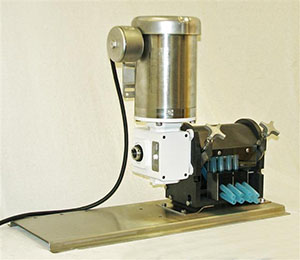

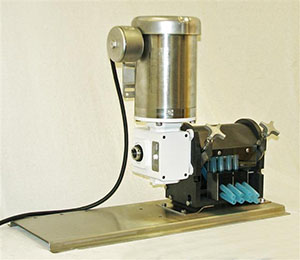

Clutch Driven Electric:

|

For short cycle dosing applications, an electric clutch drive is available. These versions are supplied with a shaft encoder and VFD motors to create a durable, adjustable, filling and dosing system pump. |

Hydraulic:

Hydraulic drives are ideal for extreme environments, mobile applications, and other situations where electric motors are not suitable. Hydraulic motors have virtually unlimited power to pump dense fluids at high flow rates and are suitable for high pressure washdown and total submersion. The speed is set by the hydraulic oil flow rate allowing full control of the pump speed. Hydraulic motors have exceptional torque at low speeds which eliminates the need of a gear box.

Maximum Flow Rate Per Channel |

Tubing Size ID |

1/8" |

3/16" |

1/4" |

3/8" |

1/2" |

mL/min |

900 |

2100 |

3720 |

7620 |

13020 |

Gal/min |

0.24 |

0.55 |

0.98 |

2.01 |

3.44 |

|

|

Mechanical:

|

Female End: for applications powered by a hydraulic motor that use a 4-hole square mount with a 1" diameter by 1.68" long shaft. Transition plate provided to direct-mount motor to pump. |

|

|

Male End: Standard configuration for non-driven shaft ends, or where the end installation will require a coupler. Provided with .375" bore to receive rotary encoder shafts and # 806 woodruff key (1/4" x 3/4") for secure coupler attachment. |

|

If the drive system has adequate torque, two or more pumps can be mechanically coupled and driven together. To do this, "left" and "right" configured pumps must be used for coupling.