Pumping

AccuStaltic Peristaltic pumps are ideal for transferring fluids where other pumping systems fail. They are designed for continuous operation with far more durability than a laboratory pump. They are a positive displacement pump so the delivery is independent of back pressure.

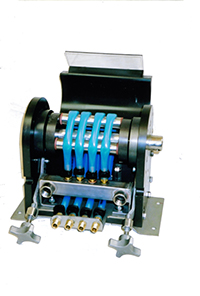

With AccuStaltic multi-channel pumps, several different manifold configurations are available that allow the flow to be divided, combined, or to provide larger flows than one tube allows. In all configurations, the ratio of the flow between tubes is kept fixed because of the single rotor acting on all channels simultaneously.

Positive displacement pumps move a specific amount of fluid as they rotate, independent of pressure. The volume of the displacement per revolution in a peristaltic pump is controlled primarily by the tubing size. The tube is filled with liquid, and the inside diameter and the length between rollers determines the volume displaced each time rollers travel over the tubes.

In theory, the exact displacement is just determined by this volume which is dependent on the inside diameter of the tube, so the volume flow rate is: volume displaced x speed of the pump. This makes it very easy to control the exact flow of the pump by controlling the speed. In practice, other factors such as tube wall thickness, tube material, pump speed and fluid viscosity have some influence on the refilling of the tube and therefore affect the flow. When high accuracy is required the pump should be calibrated with the actual working fluid and actual tube type at a typical RPM.

The following chart shows the approximate

|

|

AccuStaltic multi-channel pumps can drive up to 12 tubes simultaneously so displacements up to 260 cc/rev (0.069 Gal/rev) can be achieved. The pumps can operate up to 500 RPM creating flow rates up to 10.8 liters/min (2.8 Gal/min) on a single channel, with 130 liters/min (34.6 Gal/min) using 12 channels.

Tubes of different diameters can be used in the same pump, as long as the wall thickness is the same. This provides many ways to optimize the displacement vs. speed with one or more different fluids, on the multiple channels.

Quick reference charts have been produced to show the relation of the flow-to-tube sizes, pump speed, and number of channels. Download Flow/RPM Charts

AccuStaltic multi-channel peristaltic pumps are a fixed occlusion type of pump, meaning that the rotor and housing are very rigid and at a fixed distance. This ensures that the pump truly is a positive displacement pump. Pumps of this nature are very easy to use for precise metering of liquids because controlling the rotation controls the exact flow. Measuring the rotations determines the exact amount of fluid delivered.