Metering

AccuStaltic multi-channel peristaltic pumps are ideal for metering. These pumps are truly positive displacement pumps and are very easy to use for precise metering of liquids. Controlling the rotation controls the flow. Measuring the rotation determines the exact amount of fluid delivered.

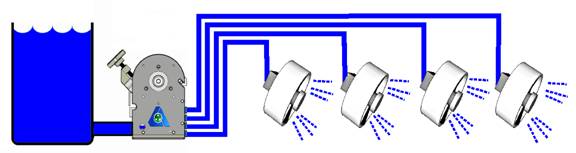

AccuStaltic multi-channel pumps can pump liquids at adjustable flow rates and are very precise when averaged over time. They deliver a constant flow regardless of variations in back pressure. This feature, combined with the multi-channel design, makes them ideal for delivering the exact same amount of fluid to several points on different length feed hoses. Our pumps achieve not only precise metering, but also accurate flow dividing.

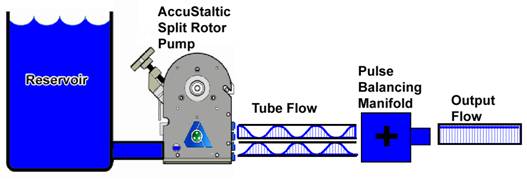

Positive displacement metering pumps are cyclic by nature and most metering pumps produce an output with a pulsing flow. Peristaltic pumps have more continuous flow with a gentle sinusoidal pulse. This pulsing can be further reduced by using an AccuStaltic pump with a split rotor. Our pumps use 2 sets of rollers offset by 60 degrees producing 2 or more flows that are 180 degrees out of phase. These flows are combine in our manifold to cancel out fluid pulses making a very smooth flow without the problems and inaccuracies of an accumulator. AccuStaltic split rotor pumps are the smoothest metering pumps without an accumulator on the market.

The flow rate on an AccuStaltic pump is directly controlled by the rotor RPM. With the proper gearbox, this can be close to zero. With no valves or back flow issues, the pump can maintain a perfectly metered flow at very low speeds. The fact that the flow can be metered accurately down to zero flow means that it can be cycled to produce measured non-continuous flows for filling and intermittent dosing applications.